What is quartz crystal ?

From the "water spirit" to "salt of industry"

Quartz crystal has been called the "water spirit" since early times. Also, Quartz crystal has been highly valued for its transparency, hardness and so on, and used as a magic ball or the like for its mysteriousness. Even now, quartz crystal is highly prized and polished quartz crystal is used for ladies' necklaces or rings. In this way, quartz crystal is used for quartz crystal products in diverse ways in our daily life. Today, quartz crystal devices are made with synthetic quartz crystal instead of precious natural quartz crystal, and has become essential device called "salt of industry", together with semiconductors called the rice of industry.

For example -Quartz watches-

The most familiar application of quartz crystal would be quartz watches. Quartz watches have 300 times higher accuracy than mechanical watches which used to be popular in old times. This high accuracy was realized by the invention of the quartz crystal unit and IC. The representative frequency of quartz watch is 32.768kHz. When the frequency of 32768Hz is continued to be divided by 2 with use of IC, the standard clock of one pulse is obtained. This one pulse advances the second hand by one second.

Piezoelectric effort and theory of quartz crystal

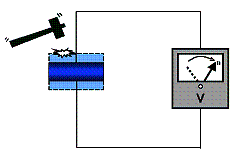

The piezoelectric effect was discovered in 1880 by French physicians Curie brothers.

(1) When mechanical pressure is applied to a crystal unit, electricity is generated on the surface (piezoelectric effect).

(2) Conversely, when electricity (voltage) is applied to the surface, mechanical strain is generated. (Inverse piezoelectric effect).

The piezoelectric effect familiar to us may be the ignition system used for lighters, stoves, burners or the like. When a button is pushed or rotated, mechanical pressure is applied to piezoelectric ceramics, generating electricity (spark) for ignition. Quartz crystal units apply this effect.

Other than quartz crystal, there are materials such as ceramics in which piezoelectric effect can be confirmed. However, quartz crystal is easily available and has the most accurate and stable frequency. For this reason, quartz crystal has been used as an essential electronic component for various devices. Quartz crystal which converts accurate mechanical vibrations to electrical signals, is used as a source of synchronous reference signals for various types of IC, color reference signal for images, watches or the like. quartz crystal devices has become a key part essential in the modern society, as represented by the fact that even a high performance computer is "a mere box" without quartz crystal devices. Quartz crystal devices includes quartz crystal units, crystal oscillators, crystal filters, SAW devices, optical devices and so on.

Quartz crystal unit

Crystallographically, quartz crystal belongs to the trigonal system and point group symmetry 32. To cite physical properties, quartz crystal (having three-fold improper rotation axis and two-fold axis of symmetry) has density of 2.654g/cm3, Mohs hardness of 7, and α-β phase transition temperature of 573 °C at which quartz crystal is transformed from α-quartz to a hexagonal β-quartz having no piezoelectricity. Quartz crystal units, such as AT cut and GT cut crystal units, have zero temperature coefficient over a broad temperature range with room temperature at the center, and therefore have excellent frequency-temperature characteristics. Moreover, quartz crystal units are extremely stable both physically and chemically, and therefore the frequency change after aging is extremely small. Owing to this excellent frequency stability, quartz crystal units are used for communication devices such as cell phones and wireless applications as well as consumer devices such as televisions, video recorders, digital cameras and computers, to provide accurate reference signals for processing a huge volume of information simultaneously and quickly. Moreover, quartz crystal units are widely used as a source of standard clock for wrist watches, stopwatches or the like.

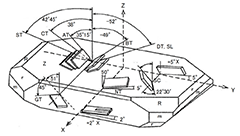

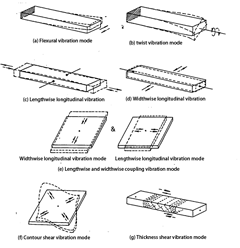

Cutting orientation of quartz crystal element, frequency, vibration mode

The quartz crystal unit has various vibration modes according to the crystallinity and piezoelectricity, and some of them have the zero temperature coefficient. As for frequency, the parameter to determine frequency is different depending on the vibration mode. For example, the frequency of a thickness shear mode resonator (AT cut, BT cut), a tuning fork type quartz crystal resonator and contour shear mode resonator (CT cut, DT cut) is decided by the thickness, the length and width of the tuning fork and the length of one side of the square, respectively. Processing technologies of these units are broadly classified into two types: The mechanically processing method and the chemically processing method.

Each vibration mode has a different frequency range and electrical performance, and therefore appropriate vibration mode should be used depending on the module.

Crystal oscillator

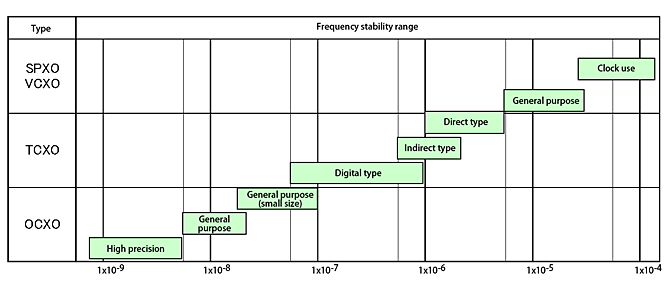

The crystal oscillator is classified in several types depending on the function. (Note: "X'tal" is an abbreviation of Crystal.)

SPXO (Simple Packaged X'tal Oscillator)

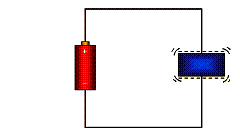

SPXO is also called XO for simplicity. In a circuit, a quartz crystal unit usually functions as an oscillating element, although it is sometimes used as a filter or a sensor. SPXO is the simplest oscillator produced by integrating a quartz crystal unit and an oscillation circuit. Just as a quartz crystal unit has temperature characteristics, an oscillation circuit has faint temperature characteristics. Also, the load capacitance which determines the oscillation frequency takes a specific value when a crystal unit is integrated with a specific oscillation circuit. Therefore, use of SPXO enables to understand the comprehensive characteristics. Especially in high frequencies, oscillation of quartz crystal can be utilized without the complicity of analog design.

TCXO (Temperature Compensated X'tal Oscillator)

TCXO refers to a temperature compensated crystal oscillator. By combining a crystal unit with a circuit having characteristics opposite to the temperature characteristics of the crystal unit, far more stable signals are obtained, as compared with the crystal unit alone. Recently, TCXO has become as small as a crystal unit, through the integration of the circuit into an IC. To cite a familiar application, TCXO is used in mobile phones.

VCXO (Voltage Controlled X'tal Oscillator)

The output frequency of VCXO is controlled by externally applied voltage. VCXO is often used in a PLL circuit and thus used for repeating installation or other various industrial instruments.

OCXO (Oven Controlled X'tal Oscillator)

Among crystal oscillators, OCXO is the most precise oscillator and therefore it is also called high-stability oscillator. As a crystal unit has arched (not linear) temperature characteristics, OXO uses a crystal unit whose temperature characteristics' inclination is zero at high temperature range, and the temperature of the crystal unit is kept at a constant value. Due to the consumption currency greater than other crystal oscillators, OCXO is used for base stations of cell phones, broadcasting instruments, measurement instruments or the like.

Crystal filter

A crystal filter refers to a filter produced by using a quartz crystal unit having a stable frequency and steep resonance characteristics relative to the temperature change.

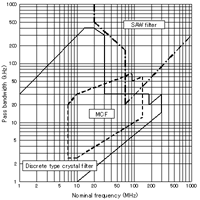

A band-pass filter having its nominal frequency in the range of several kHz to several hundreds MHz and the pass bandwidth in the range of several tens Hz to several hundreds kHz is used for a wireless communication equipment and wire communication equipment.

The crystal filters are classified into the discrete type crystal filter and the monolithic crystal filter.

Discrete type crystal filter

The discrete type crystal filter is also called the general crystal filter produced by combining one or more quartz crystal units, a coil and a capacitor and storing them in a case in which a Jaumann circuit is mainly used.

Monolithic crystal filter (MCF)

The monolithic crystal filter refers to a filter produced by arranging two pairs of more electrodes on one quartz crystal plate and using a plurality of resonance characteristics due to acoustic coupling between the electrodes.

The monolithic crystal filter has a significant restriction in designing and manufacturing the filter, as compared with the discrete type crystal filter, and therefore the range of realizable characteristics (nominal frequency, pass bandwidth, etc.) is limited.

The monolithic crystal filter has features such as downsizing and light weight because one quartz crystal plate works as a plurality of quartz crystal units without using the Jaumann circuit needing the coil.

SAW device - Surface acoustic wave device

Literally translating the Japanese term, the SAW device is called the elastic surface wave device. An elastic surface wave means a wave transmitted on an elastic body (solid).

Features of SAW

(1) High frequency vibration modes (60MHz or more) are used.

(2) The electrode has a unique shape (comb-like electrode).

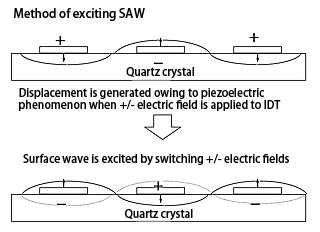

Method of exciting SAW

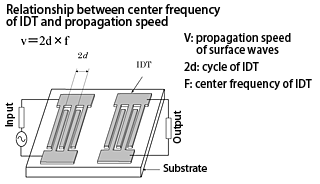

SAW is excited by applying an electric field to IDT arranged on a uniquely shaped piezoelectric substrate. IDT is an abbreviation of Interdigital Transducer, and is called the comb-like electrode literally translating the Japanese term. When the center frequency of IDT, the cycle of IDT, and the propagation speed of the surface wave are defined as f, 2d and v respectively, v is given as follows.

v=2dxf

The propagation speed of a surface wave is different depending on the material of the substrate, and about 3100m/sec in the case of ST cut quartz crystal.

Applications of SAW

The SAW device is used as a filter or a resonator for consumer devices.

|

|

| Relationship between center frequency of IDT and propagation speed | Method of exciting SAW |

Optical device

The quartz crystal has the function of both dividing one light beam into two beams and changing the direction of vibration of light. These functions are called birefringence, deflection, or optical rotatory power. Representative optical devices using such properties would be optical low-pass filters for video cameras or digital cameras as well as phase plates (wavelength plate) for an optical disc and magneto optical disc apparatus.

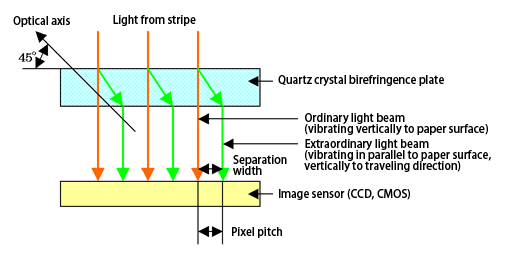

Optical low-pass filter (birefringence plate)

In a color camera with a CCD or CMOS sensor, a color is reproduced by using a color separation filter, and therefore when a stripe pattern with fineness exceeding a certain level is photographed, an output image is colored even though the object is not actually colored. To overcome this drawback, the stripe pattern with fineness exceeding a certain level is blurred by using the birefringence plate (optical low-pass filter) which doubles one light beam. A fine stripe pattern has a high (spatial) frequency and a rough stripe pattern has a low (spatial) frequency.

Phase plate (wave plate)

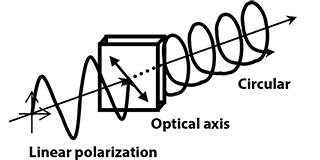

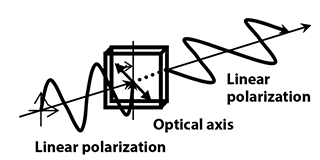

Light falls on a quartz crystal plate in a direction perpendicular to the optical axis travels in the quartz crystal plate in the same direction. However, the direction of vibration is changed by 90 degrees (The speed between the ordinary light beam and extraordinary light beam is different). The difference between the phases of two light beams at the time of getting out of the quarts crystal plate depends on the thickness of the crystal plate. Therefore, the polarization state can be controlled by changing the thickness of the plate. By using these properties (linear polarization, circular polarization, elliptical polarization) of quartz crystal, 1/4 wavelength plates or 1/2 wavelength plates are used as a pickup of CD, DVD or the like.

|

|

| Drawing of principle of 1/4 wavelength plate | Drawing of principle of 1/2 wavelength plate |

Synthetic quartz crystal

The synthetic quartz crystal is an alpha-quartz single crystal grown by a hydrothermal method. The meaning of synthetic quartz crystal involves a quartz crystal right or left in an as-grown state or in a processed Lumbered state.

Growth method for synthetic quartz crystal

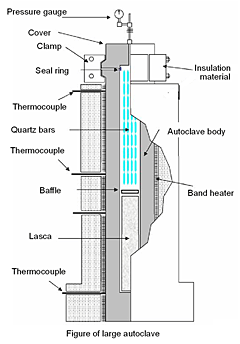

The synthetic quartz crystal is grown by the hydrothermal method using a pressure vessel called an autoclave in high temperature and high pressure condition. The principle relates to artificially reproducing an environment similar to the process in which the natural quartz crystal grows inside the earth crust. With the use of this process quartz crystal can be obtained during an extremely short period of time with a high yield.

The autoclave is vertically divided into two chambers by a baffle. The upper chamber is a crystal growth region in which a seed crystal is attached, and the lower chamber is a dissolving region in which the natural quartz crystal (Lasca) as the raw material is set. The autoclave is filled with dilute alkaline solution (sodium hydroxide or sodium carbonate) to about 80% level of the free space in the autoclave. It is sealed with a cover and seal ring and then heated. When the autoclave is heated to 300°C degree at the upper temperature and 400°C degree at the lower temperature, the pressure is increased to 140MPa maximum by an expansion and compression action of the solution.

Under the high-temperature and high-pressure environment, the raw material in the lower chamber starts dissolving in the alkaline solution to super saturate SiO2 solution. The super saturate solution moves upwards by thermal convection to be in a super saturate state in the upper growth region because of the temperature difference in the autoclave, and thus the quartz crystal starts to precipitate and grow on the seed crystal.

Thereafter, the solution moves downwards to the lower chamber of autoclave to be heated, absorb more of the raw material again and moves upwards by convection. The synthetic quartz crystal continuously grows by repeating such the process.